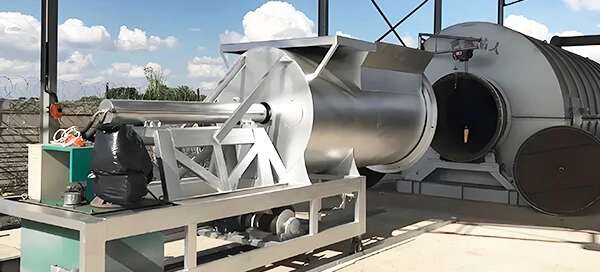

The CSHB eco-friendly pyrolysis plant converts waste tires, plastic and rubber into fuel oil or non-standard diesel for industries like cement factory, metallurgy plant, agricultural machinery, ships, and more. We offer two options to meet diverse market needs: batch type and continuous type pyrolysis plants. Additionally, our team can design custom capacities tailored to your specific project requirements, ensuring a perfect fit for your operations. Besides, we also provide a distillation system to refine the pyrolysis oil or used engine oil to diesel.

- Raw Material: Tire, plastic, rubber, municipal waste, oil sludge, food waste

- Output Material: Pyrolysis fuel oil, non-standard diesel

- Capacity: 5~100 tons/day (or higher)

- By Product: Steel wires, carbon black

- Usage: Kilns, boiler, furnace, heavy machinery, boats, oil burners

Get A Price Now!

Working Process (Batch Type)

-

Step 1: Feeding process. Waste tires, plastic or other type wastes are fed into the pyrolysis reactor manually or through an automatic feeder. For continuous pyrolysis lines, a seamless feeding system is essential to maintain an oxygen-free environment, ensuring safe and efficient reactor operation.

-

Step 2: Heat. Once material is fed, the reactor will be heated to a specific temperature range (typically 300°C to 500°C) using fuel sources such as gas, heavy oil, pyrolysis oil or even coals. Under the right high temperature, the raw material will decompose and start generating oil vapor, syngas, and carbon black.

-

Step 3: Purify. The syngas and oil vapors pass through a gas separator, which removes impurities from the oil vapor. The oil vapor will then enter the condenser for further processing, while the impurities and heavy oil slag will be left inside a slag tank.

-

Step 4: Condensing. The oil vapors are cooled in a condensation system, converting them into liquid pyrolysis oil. This oil can be further refined or directly used as fuel. Meanwhile, the non-condensable combustible gas is filtered and reused to sustain the heating process.

-

Step 5: Collection and Storage. The final products—pyrolysis oil, carbon black, and steel wires—are collected and stored. The oil is stored in a temporary storage tank, the carbon black is packed for industrial use, and the steel wires are extracted for sale.

-

Step 6: Exhaust Gas. During the pyrolysis process, there will be exhaust gas generated from the raw material, which needs to be purified before emitted to the environment. The spraying tower and dedusting system and other devices can be equipped to neutralize the acid and clean the gas before emission to the atmosphere.

This process is totally eco-friendly, efficient, and resource-recovering, turning waste into valuable products while minimizing environmental impact.

Specification

| Equipment Size |

1400×5000 mm |

1400×5500 mm |

2600×7700 mm |

2800×7700 mm |

2800×8000 mm |

2800×8000 mm |

| Thickness |

14 mm |

14 mm |

16 mm |

18 mm |

20 mm |

20 mm |

| Capacity |

3 tons/day |

4-6 tons/day |

10-12 tons/day |

13-15 tons/day |

15-16 tons/day |

20~25 tons/day |

| Power |

10 kW |

10 kW |

18 kW |

20 kW |

20 kW |

20 kW |

| Ractor Material |

Q345R |

Q345R |

Q345R |

Q345R |

Q345R |

|

| Heating Method |

Fuel gas |

Fuel gas |

Fuel gas |

Fuel gas |

Fuel gas |

Fuel gas |

| Installation Area |

80 m2 |

100 m2 |

200 m2 |

250 m2 |

300 m2 |

300 m2 |

| Oil for Heating |

20 kg/h |

20 kg/h |

20 kg/h |

20 kg/h |

20 kg/h |

20 kg/h |

| Need Installation |

No |

No |

Yes |

Yes |

Yes |

Yes |

| Weight |

18 tons |

20 tons |

32 tons |

35 tons |

38 tons |

38 tons |

| Labor |

2 workers |

2 workers |

2 workers |

2 workers |

2 workers |

2 workers |

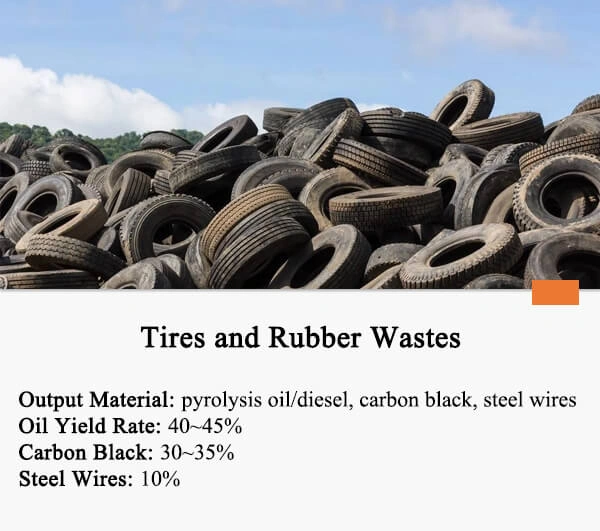

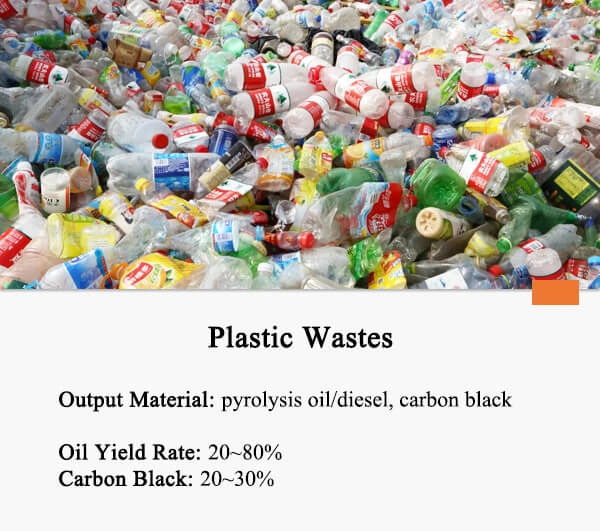

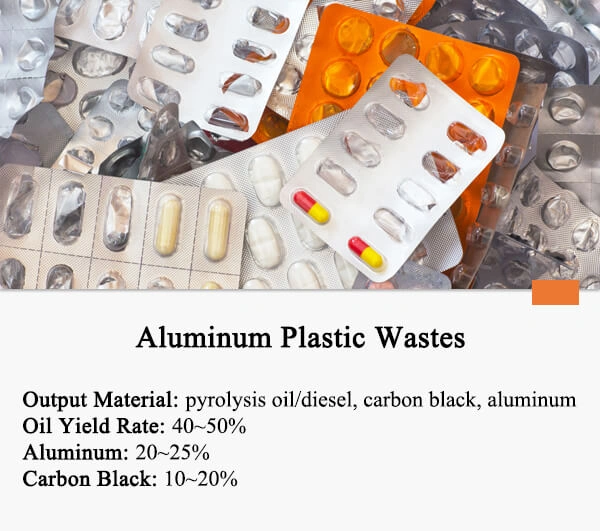

Suitable Material

Show Room

Have Any Question? Get In Touch Please !

If you have any question about pyrolysis and distillation systems, Please do not hesitate to contact us. We would reply to you as soon as possible.