A tire shredder is the most efficient way to process large volumes of waste tires into small, uniform chips. Powered by dual motors, each connected to a shaft via couplings and reducers, the shredder uses hardened blades and hooks to grip and tear tires with precision. The shredded material is then passed through a screening system to ensure consistent chip size and quality. As a key component of any tire recycling line, this equipment maximizes productivity while supporting sustainable waste management practices.

- Feeding Diameter: 800~2800 mm

- Output Size: 50~200 mm

- Capacity: 1~35 ton/h

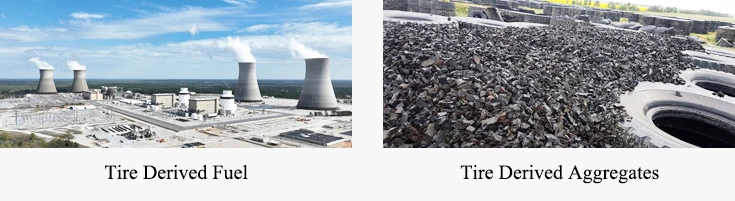

- Application: Tire derived fuel (TDF), tire derived aggregates (TDA), saving space for tire storage or transportation.

Working Process

-

Step 1 (Optional): Use a tire debeader to extract thick steel wire rings from tire beads. Powered by a hydraulic cylinder, this machine efficiently removes bead wires. Customers can opt for a double-hook debeader to simultaneously extract wires from both sides of the tires, enhancing productivity.

Step 1 (Optional): Use a tire debeader to extract thick steel wire rings from tire beads. Powered by a hydraulic cylinder, this machine efficiently removes bead wires. Customers can opt for a double-hook debeader to simultaneously extract wires from both sides of the tires, enhancing productivity. -

Step 2 (Optional): A tire cutter can be used to slice large tires into shorter segments, making them suitable for smaller shredders. This step is unnecessary if a large-capacity shredder is already in place, saving time and resources.

Step 2 (Optional): A tire cutter can be used to slice large tires into shorter segments, making them suitable for smaller shredders. This step is unnecessary if a large-capacity shredder is already in place, saving time and resources. -

Step 3: Tires are fed either manually or through a tire feeder onto a conveyor belt, which transports them to the shredder’s hopper. The shredder blades then process the tires into smaller, uniform pieces, ready for further separation.

Step 3: Tires are fed either manually or through a tire feeder onto a conveyor belt, which transports them to the shredder’s hopper. The shredder blades then process the tires into smaller, uniform pieces, ready for further separation. -

Step 4: A trommel screen or disk filter system separates small tire chips from larger ones. Oversized chips are sent back to the shredder for additional processing until they meet the required size, ensuring consistent output for downstream applications.

Step 4: A trommel screen or disk filter system separates small tire chips from larger ones. Oversized chips are sent back to the shredder for additional processing until they meet the required size, ensuring consistent output for downstream applications.

Specification

| Model | Input Tire Diameter | Output Chip Size | Capacity | Motor |

|---|---|---|---|---|

| DS-800 | 800mm | 50*50mm | 1-2T/h | 2*22kw |

| DS-1200 | 1200mm | 60*60mm | 3-5T/h | 2*45kw |

| DS-1600 | 1600mm | 75-150mm | 6-8T/h | 2*75kw |

| DS-1800 | 1800mm | 75-150mm | 7-10T/h | 2*90Kw |

| DS-2000 | 2000mm | 75-200mm | 10-15T/h | 2*110kw |

| DS-2400 | 2400mm | 100-200mm | 20-30T/h | 2*132kw |

| DS-2800 | 2800mm | 150-200mm | 25-35T/h | 2*160kw |

Show Room

- The planetary reducer features a high-torque design, enabling the shredder to handle heavy-load operations with ease.

- Special heat treatment is applied to the shredder blades, providing a hardened surface that effortlessly cuts through tires and steel.

- Reverse rotation capability allows for easy maintenance or clearing of hard foreign objects that may accidentally enter the shredder.

- A current monitoring system ensures the shredder remains in optimal working condition at all times.

- Equipped with Siemens motors and other top-tier components, the machine is built to deliver the longest possible service life.

Applicatons

Have Any Question? Get In Touch Please !

If you have any question about tire recycling equipments, Please do not hesitate to contact us. We would reply to you as soon as possible.