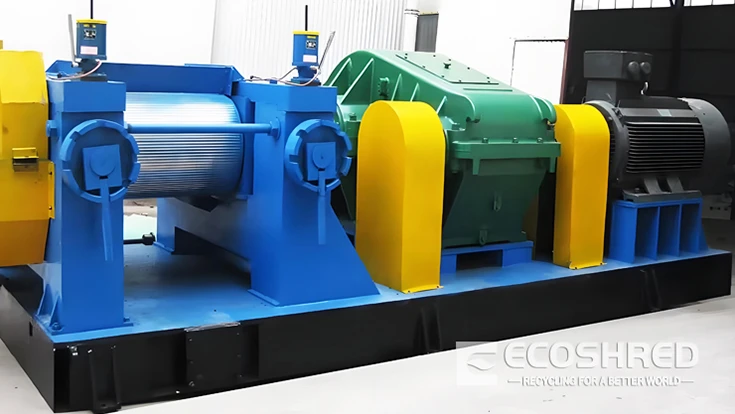

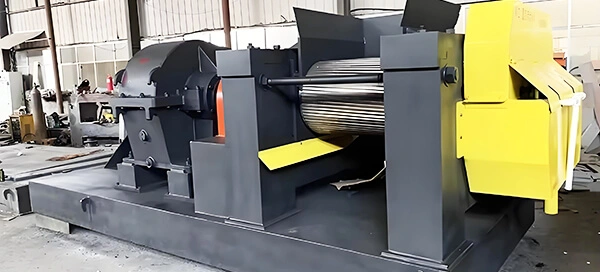

The RCM tire roller crushing line is a versatile and cost-effective tire recycling solution, suitable for processing waste tires into both rubber crumbs and powder. Its core working principle is to crush tires between two grinding rollers rotating at different speeds. The rubber is then crushed and screened into the ideal size, followed by the use of a magnetic separator and nylon separator to remove steel wires and nylon fibers. The system is easy to install, requires minimal space, and is perfect for new investors seeking a quick start.

- Tire Type: Car tire, radial tire, OTR tire

- Output Material: 0.4~5 mm rubber granules (5~40 mesh)

- Capacity: 300~3000 kg/hour (or higher)

- Rubber Purity: 99.8%

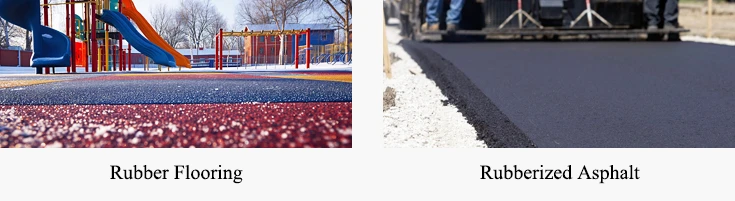

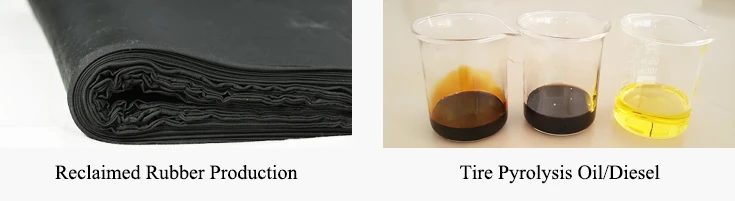

- Usage: Rubber tiles, rubberized asphalt, reclaimed rubber, pyrolysis oil.

Working Process

-

Step 1: Feed waste tires into the tire shredder for primary shredding, producing tire chips under 150mm. Depending on tire size and shredder capacity, a tire debeader or cutter can be added to the process. The tire chips can be directly transferred to the crusher or stored in a temporary storage silo.

Step 1: Feed waste tires into the tire shredder for primary shredding, producing tire chips under 150mm. Depending on tire size and shredder capacity, a tire debeader or cutter can be added to the process. The tire chips can be directly transferred to the crusher or stored in a temporary storage silo. -

Step 2: Transfer the tire chips to the main crusher via a belt conveyor. The crusher and its auxiliary machines form a closed-loop system, allowing the tire chips and larger rubber granules to get grinded repeatedly between the two grinding rollers. This ensures continuous crushing until the material reaches the desired size for customer use.

Step 2: Transfer the tire chips to the main crusher via a belt conveyor. The crusher and its auxiliary machines form a closed-loop system, allowing the tire chips and larger rubber granules to get grinded repeatedly between the two grinding rollers. This ensures continuous crushing until the material reaches the desired size for customer use. -

Step 3: Two-stage vibrating screens are used to filter the rubber granules or powder. The primary screen separates smaller granules, which are then passed to the secondary screen for final sizing. Each vibrating screen is paired with a magnetic separator to ensure complete removal of steel wires.

Step 3: Two-stage vibrating screens are used to filter the rubber granules or powder. The primary screen separates smaller granules, which are then passed to the secondary screen for final sizing. Each vibrating screen is paired with a magnetic separator to ensure complete removal of steel wires. -

Step 4: An airflow nylon separator is installed after the second magnetic separator. The wire-free rubber is transported to the nylon separator via a pneumatic conveyor. Utilizing density differences, the rubber granules are separated from nylon fibers and collected as the final product ready for sale.

Step 4: An airflow nylon separator is installed after the second magnetic separator. The wire-free rubber is transported to the nylon separator via a pneumatic conveyor. Utilizing density differences, the rubber granules are separated from nylon fibers and collected as the final product ready for sale.

Specification

| Model | Capacity | Output Rubber Size | Purity | Crusher Power | Required Worker | Required Space | Power Consumption |

|---|---|---|---|---|---|---|---|

| RCM-500 | 300~500 kg/h | 5~40 mesh | 99.70% | 55 kW | 4~5 people | 12*8*5 m | 65 kWh per hour |

| RCM-1000 | 500~1000 kg/h | 5~40 mesh | 99.70% | 110 kW | 3~4 people | 21*8*5 m | 136 kWh per hour |

| RCM-1500 | 1000~1500 kg/h | 5~40 mesh | 99.70% | 132 kW | 3~4 people | 27*8*5 m | 151 kWh per hour |

| RCM-3000 | 2000~3000 kg/h | 5~40 mesh | 99.70% | 200 kW | 2~3 people | 39*10*5 m | 223 kWh per hour |

| Note: we can customize any capacity based on customer’s requirement. | |||||||

Show Room

- Wide Capacity Range: large, medium and small project can all be satisfied by the tire roller crushing line.

- Simple Structure: space-saving design with low maintenance costs, suitable for large-scale tire recycling projects.

- Strong Adaptability: capable of processing various tire types (e.g., truck tires, car tires, OTR tires).

- Low Initial Investment: Lower costs in equipment, electric consumption, and land preparation.

- Easy Operation: User-friendly controlling panel, suitable for small to medium-sized tire recycling businesses.

- Large Output Size Range: Can produce different sizes (0.4~5 mm) as the market needs, including both rubber crumbs and powder.

Applicatons

Have Any Question? Get In Touch Please !

If you have any question about tire recycling equipments, Please do not hesitate to contact us. We would reply to you as soon as possible.